Measurement

Integrated flow measurement and automation solutions, from the wellhead to final point of sale

We deliver accurate and reliable measurement for the transportation, distribution, and storage of energy products by truck, rail, vessel, aviation, and pipeline.

Making measurement smarter

Understand the health of your pipeline assets and optimize the transportation and storage of energy products across the upstream, midstream, and downstream value chain for faster and safer product delivery with smart, connected flow measurement. Gather insights to improve decision-making and prevent operational risk through integrated digital automation solutions, remote monitoring, and measurement technologies that connect what is happening in the field with your business ERP.

We have the right products and systems to help with any application challenge. Experience the simplicity of dealing with one supplier as we bring together reliable and accurate measurement and control systems, automation, and key data insights.

- Expertise

- Measurement technologies

- System integration

- Digital automation

- Remote support

Featured products and solution models

Smith Meter® AccuLoad® IV

The AccuLoad IV family of electronic preset control systems provides safe and reliable control as well as accurate measurement for custody transfer loading and unloading of petroleum liquid products.

Continuously refined for over 35 years to provide an optimal suite of features and flexibility, AccuLoad IV is tailored for current operations and adaptable to future growth and enhancements.

- Individually configurable loading arm functions

- Up to six products for each load arm, with simultaneous operation of all load arms

- User-configurable inputs and outputs

- Additive control for metered, smart, and piston injectors

- Digital or analog valve flow control

- Single- and dual-channel meter pulse inputs

- Fully configurable flow profile

- Alarm monitoring with configurable action

- Standalone operation or remote-controlled through-communication link, and browser-based remote access

- Suite of measurement profiles

- Extensive security and onboard diagnostics

- Built-in virtual load rack (VLR) simulates loading rack equipment for diagnostics and training

- Boolean/algebraic processing

- Automatic flow control with recovery

- Linux operating system with ethernet and serial communications for networking

Smith Meter® Turbine Meter

A rimmed, rotor-type meter with helical blades, the TechnipFMC Sentry series turbine meters utilizes both an upstream and downstream stator and has tungsten carbide bearings with a hydrodynamic thrust balance system. It provides highly accurate measurement required for custody transfer of petroleum liquids such as crude oil and refined products in larger pipelines.

- Bidirectional flow allows the meter to accurately register flow in either direction

- Multiple pickup coils are used when direction sensing or pulse security is required

- A third pickup coil is available to drive auxiliary equipment, such as a back-up counter or prover. ±0.10% and ±0.07% linearity available

- High-resolution (HR) output available on 4″ through 8″ meters to increase the pulse output per unit volume to allow proving with a smaller-size pipe prover

Smith Meter® PD Meter

A single-case positive displacement meter designed for maximum accuracy and reliability, the PD Meter is ideal for loading rack service and custody transfer of petroleum products. Applications include gasolines and oxygenates, ethanol, kerosene, diesel fuel, jet fuels, and fuel oils.

- Minimal slippage for outstanding linearity and maximum accuracy

- Unique flow pattern minimizes pressure drop to less than 3.2 psi at extended maximum flow

- Unique design with only three moving parts results in low initial cost and minimum maintenance; direct pulse output eliminates the mechanical drive train resulting in fewer parts to fail and removes the need for a packing gland

- Horizontal rotor and specially designed journal bearings minimize wear and lead to a long service life

- Polyketone blades show decreased wear over time keeping the meter stable between proving intervals and resulting in time and cost savings

Smith Meter® Ultra™

The Smith Meter® Ultra™ 8c Liquid Flowmeter is an eight-path ultrasonic meter for custody transfer measurement of petroleum products. The multiple measurement paths accurately resolve difficult flow profiles, maintaining linearity and repeatability over the widest range of conditions.

The Ultra 8c exceeds the most demanding performance specifications on light to heavy petroleum products without the need for flow conditioning.

- Meets OIML R117 and API requirements for custody transfer with +/-0.12% linearity over 15:1 normal flow range

- Eight transducer paths precisely measure swirl and cancel any resulting transverse velocities for highly accurate performance

- Eight measurement paths and dynamic profile compensation provide extremely linear performance

- Cancellation of swirl permits installations with 5D upstream straight run without flow conditioning

- Powerful signals penetrate the heaviest fluids maintaining measurement integrity and preventing signal loss

- High-speed signal processing exceeds API requirements, proving in fewer runs and/or smaller prove volumes

Sening® Tank Truck Package

The Sening® Tank Truck Package combines our MultiTask tank truck management systems with the high precision Smith Meter® rotary vane positive displacement meter and Sening® gas extractor technology into an economical solution for metering hydrocarbon liquids such as fuel oil and gasolines from road tankers. The gas extractor and meter are combined in one aluminum housing to save space and reduce the weight of the truck.

Sening® MultiTask is a tank truck management system designed to improve safety and reliability with a variety of applications to support truck safety, efficiency and support cost control while out on the road.

- Field-proven hardware with over 14.000 units in the field worldwide

- Modular system with versatile expansions

- 30 different manageable products with 4 meter factors for each product

- Data communication via FTL

- Different operator and print report languages available

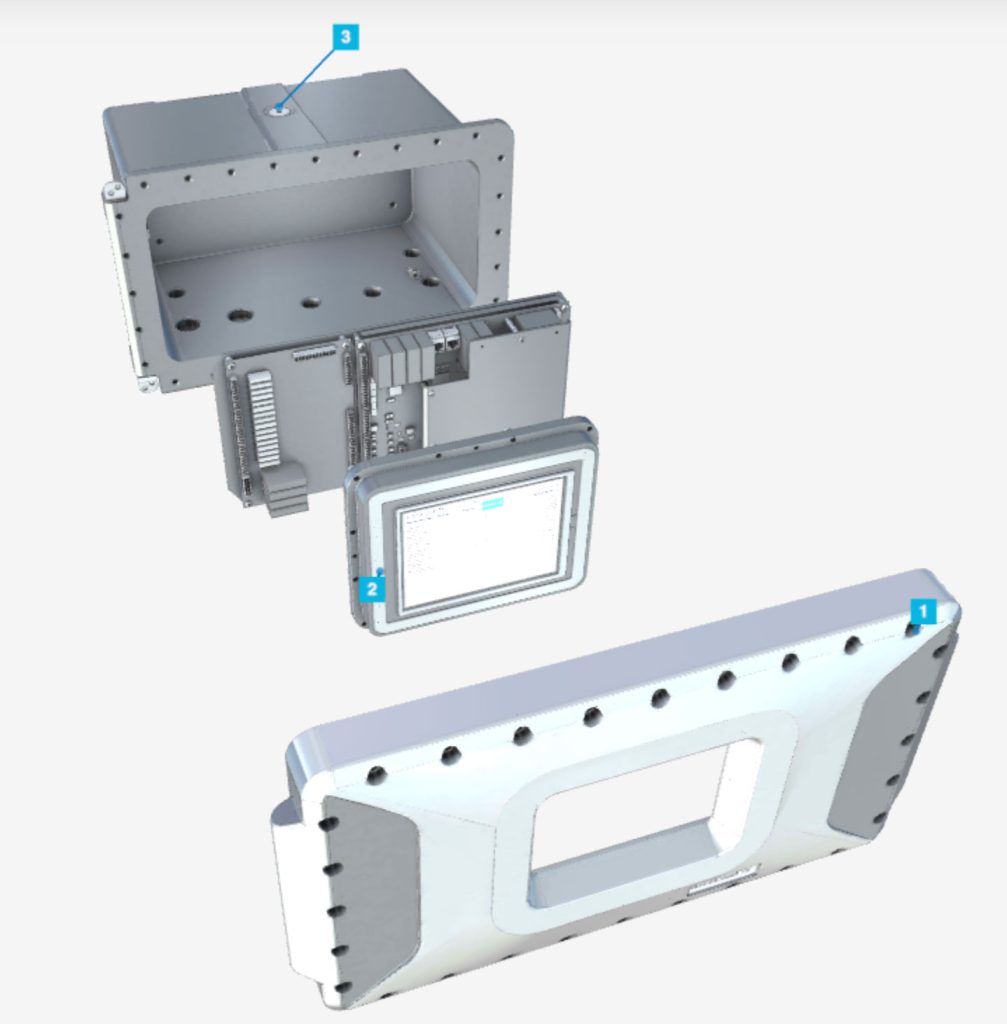

Product spotlight: Smith Meter® AccuLoad® IV Split Architecture (SA)

The next generation of preset batch controllers. The Smith Meter AccuLoad IV SA continues to deliver proven reliability, accuracy and drive cost efficiencies through expanded I/O capabilities with multiple I/O boards in a single housing and increased supported load arms.

Related information

Additional information

- Site installation supervision and commissioning

- Remote diagnostic support by phone, email, and internet

- Field service available for on-site troubleshooting and repair

- Specialist support for periodic maintenance and audits

- Operations and maintenance contracts

- Remote monitoring and condition-based maintenance

- Customer training

- Spares and parts management solutions

- Consulting services

- System modifications and upgrades

- Equipment buy-back and remanufactured equipment with Revolve program

Our solutions are complemented by global engineering and application know-how, project management, global services, training, and remote support. We offer greater reliability, reduced operational costs, and the simplicity of one supplier.

Guidant’s Flow Research and Test Center is the only facility in the world that can test meters over the widest dynamic measurement range. It demonstrates product functionality, reliability, and accuracy on a full-scale setting in real time. Our test center guarantees optimum verification of meter performance.

- Accredited to ISO/IEC17025:2017 by NVLVAP (NVLAP Lab Code 200939-0)

- Laboratory Scope of Accreditation

- Traceable to international standards and meets all requirements for OIML

- Maximum Flow capability of 4 to 42,000 bph (0.6 to 6,675 m3/h)

- Viscosity Testing range of 2 to 500 cSt (2 to 500 mm2/s)

- Can test meter sizes from 1 to 30 inches (25 to 750 mm)

- Dynamic testing range of 10 to 1,000,000 Reynolds number